Research Areas in Food Ingredient Science Technology

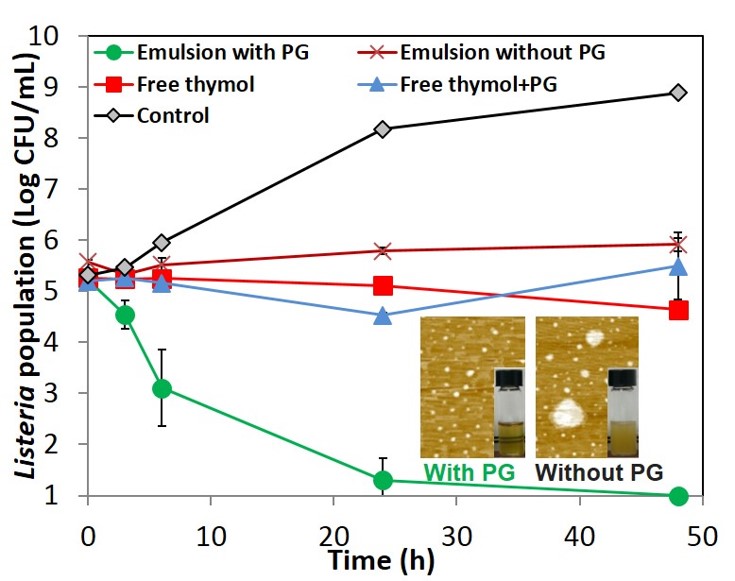

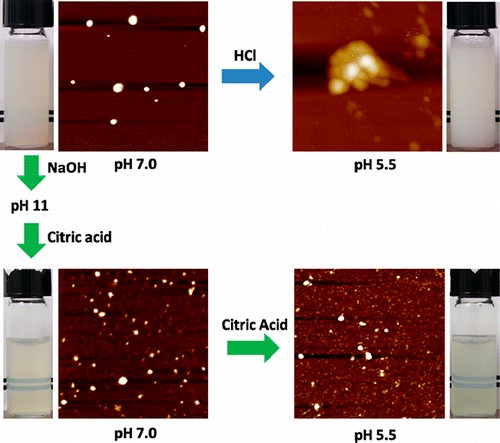

Antimicrobial preservatives are used in or on food products to inhibit the growth of pathogenic and spoilage microorganisms to ensure microbial safety and quality. The molecular structures of antimicrobials determine they may separate out of the aqueous phase and bind with food components due to attractive hydrophobic and/or electrostatic interactions. These physical phenomena require delivery systems to evenly distribute antimicrobials at the application site and reduce the interference of food components so as to enhance the availability of antimicrobials to interact with microorganisms.

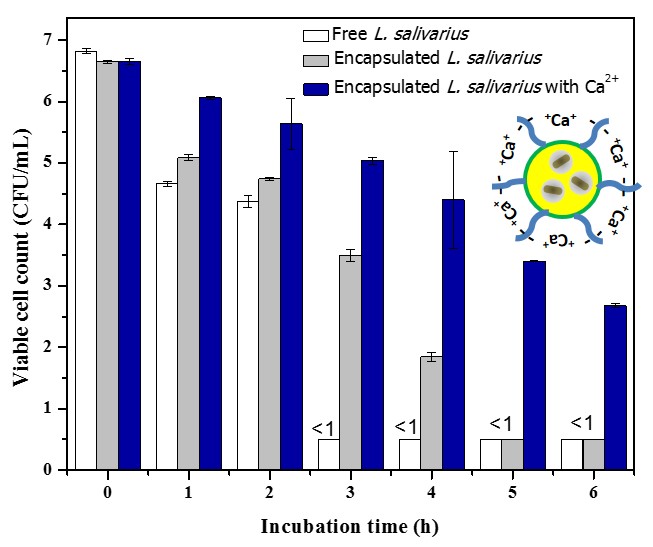

Diets are the foundation of human nutrition and health. With the increasing scientific evidences of bioactive dietary components and beneficial bacteria promoting health, there are great needs of technologies to incorporate these ingredients in food products to maintain food quality, prevent the activity loss during processing and storage of foods and post-ingestion, and deliver bioactives to the target site. Delivery systems are studied to address these needs to produce functional foods.

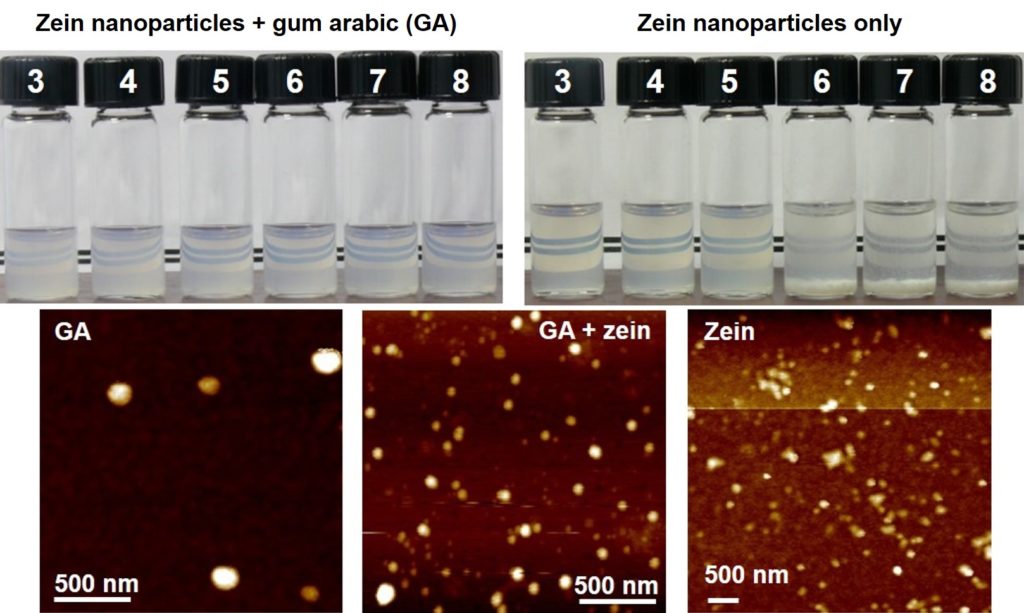

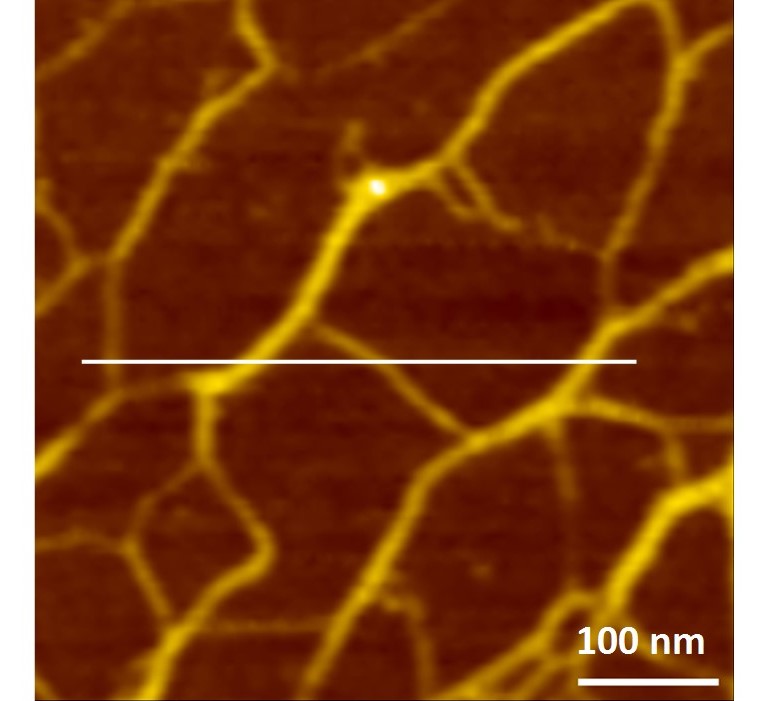

Colloidal particles have a dimension typically from several nanometers to about 1 micrometer, but the dimension of colloidal systems can be well over 1 micrometer if they share common physical phenomena. Colloidal particles are native to many food products, with milk being a common example because of the dimensions of casein micelles and fat globules. Colloidal science is significant to the manufacturing of many food products that have solid (a sol), liquid (an emulsion), or gaseous (a foam) particulates dispersed in a liquid or solid continuous phase. Research goals are to create colloidal systems with unique sensory and functional properties and maintain these properties during shelf-life storage.

Many food ingredients are used to provide rheological, interfacial, and mechanical properties that are needed to produce food products with unique quality attributes. Rheological properties are important to thickening, gelation, and stabilizing functions that are correlated to viscosity, viscoelasticity, and yield stress. From the materials perspective, self-assembled structures of food molecules with and without assistance of external forces can be fabricated utilizing physicochemical and biochemical properties of food molecules to enable the desired functional properties.

Food biopolymers, proteins, and polysaccharides are common ingredients in food preparation. Food biopolymers also form structures of native and processed food products to determine quality and the digestion and bioavailability of major and minor nutrients and bioactives important to health. Understanding physical, chemical, biochemical, and biological properties of food biopolymers and food products therefore is important to improve their functional properties for optimized nutritional and health benefits.

Contact Information

Dr. Qixin Zhong

qzhong@utk.edu

865-974-6196